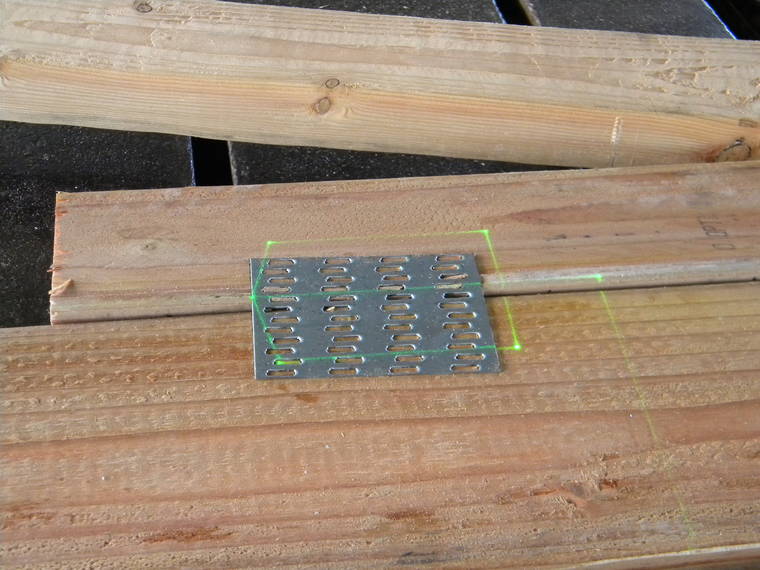

The old carpenters’ adage, “measure twice, cut once” is taken to a new level at HPM Building Supply’s Keaau factory, where computers do the measuring and lasers show where to make the cuts and attach the hardware.

HPM, short for Hawaii Planing Mill, is a 99-year-old employee-owned company long known for its prefabricated wall panels and trusses and custom-made metal roofing. Now it’s moving into factory-built modular homes, with entire housing units built in the factory and transported to home sites.

Workers Friday were busy laying out lumber, leveling, cutting and hammering, all under the guidelines set by computer-aided machinery.

Individual components of factory built housing have long been an HPM specialty. But putting them all together to build an entire home module in the factory has met with some resistance, as Hawaii County works on creating a construction code to accommodate advances in home building.

At issue is an appendix to Bill 179, a 197-page consolidation of building, plumbing, electrical and energy codes to create a streamlined process replacing numerous permits with just one construction permit. The County Council has scheduled final reading of the bill Wednesday, but council members have sponsored several more amendments before it gets its last vote.

Affordable housing advocates support the concept as a way to put more homeless or potentially homeless families into housing more cheaply and quickly. The factory at Shipman Business Park can produce two modules weekly, at the cost to the consumer of under $100,000 for a two-bedroom home.

Trucking costs, lot costs, building a foundation and electrical, plumbing and sewer hookups would add to the price. Trucking a unit from Hilo to Kailua-Kona, for example would run $800-$1,200.

In comparison, conventionally built houses in Hawaii are running about $290-$780 a square foot, according to Rider Levett Bucknall, an international leader in the construction industry.

“We’re really trying to target that affordable gap of families who cannot afford a home today,” by producing homes from 288-720 square feet, said Jason Fujimoto, HPM president and CEO.

The factory built housing appendix is a statewide code that’s been in the building code since 2012 and is being used on Oahu and Kauai to create affordable communities to house homeless families. But it’s become controversial after Hawaii County consulted with HPM over the past two years to make the code more workable.

“HPM Building Supply has positioned itself to build (factory built homes) and worked closely with the County of Hawaii Building Division for the last two years to develop and implement policies that will fast-track FBH,” said Christopher Delaunay, government relations manager for the carpenter-backed Pacific Resource Partnership in a letter to the editor of the newspaper. “While they were developing Bill 179 and FBH policies, members of the public were left in the dark on how the bill came together.”

Fujimoto described the consultations with the county as a collaborative process focused on solving a problem. Because modular housing is a new concept in the county, it doesn’t fit the old construction code and adaptations needed to be made, he said. The company’s intent is to offer the housing first to its employee-owners and nonprofits and then to regular consumers.

“This was about how do we work together to help the community, not to give HPM a single sole advantage,” Fujimoto said. “It’s about building a home turnkey in fact and it ensures the building is built using the same local code.”